![Schematic diagram depicting oil and gas generation. [Credit: WSGS] Schematic diagram depicting oil and gas generation](../images/energy/generation-thumb.jpg) How are oil & gas formed?

How are oil & gas formed?

Crude oil and natural gas are hydrocarbons that originate from algae, plankton, and other organic material. This biologic material settles to the bottom of a sea, is incorporated into the mud,

and is subsequently buried by thick layers of sediment. The weight of the overlying sediment increases the temperature and pressure of the organic-rich mud. If these temperatures and pressures are sustained for

long periods of time (~10 million years), the organic material is converted into kerogen and bitumen. As temperatures continue to increase, the kerogen undergoes a process called catagenesis

(also called “thermal cracking”) in which it is converted into crude oil. Ideal temperatures for crude oil formation are called the “oil window,” and are approximately between 150°

and 300°F (65° and 150°C). Natural gas begins to form at temperatures higher than approximately 300°F (150°C). Click to enlarge image at right.

Oil & Gas Exploration![Schematic diagram showing the basics of collecting 2D seismic data. [Credit: WSGS] schematic diagram of 2D seismic data collection](../images/energy/shooting-seismic22.jpg)

Exploration geologists and engineers use a variety of techniques to locate subsurface oil and natural gas. Data from nearby wells, regional geology,

computer models, satellite imagery, and mapped surface oil seeps can help predict where a productive oil well might be located.

Seismic surveying is one of the most effective methods of finding oil and gas because it enables geologists to map underground formations and structures. A noise

source—either a vibrating/thumping truck or an explosive discharge—directs sound waves through the subsurface. The waves reflect off the different rock layers and structures.

Geophones record the time it takes for the waves to return to the surface. The raw seismic data are then processed and interpreted to determine the possibility of oil and/or gas.

Three-dimensional seismic surveys allow geologists to make even more accurate interpretations and predictions of oil and gas deposits.

Drilling exploration wells confirms whether oil and/or gas exists in a suspected area or formation. While some exploration wells lead to the successful discovery of hydrocarbons, others turn

out to be “dry holes.” On occasion, exploration wells help locate hydrocarbons in rock layers other than the original target formation.

Conventional Oil & Gas Traps

![Three common types of oil and gas traps in Wyoming. [Credit: WSGS] common oil & gas traps](../images/energy/traps.png)

Oil and natural gas will migrate vertically and laterally through porous rock formations, such as sandstone and limestone, as well as through faults and natural fractures until an impermeable barrier stops their movement.

These barriers to hydrocarbon movement are commonly called traps. Oil and/or natural gas accumulate in these traps to form large hydrocarbon deposits.

The rock layer in which the hydrocarbons are trapped is called the reservoir.

There are two main categories of conventional oil/gas traps: structural and stratigraphic. Structural traps form when rock layers are deformed and the resulting geometry

prohibits the hydrocarbons from migrating any further. Common structural traps include anticlinal folds and faults. Salt Creek, Wyoming’s most productive (and nearly oldest)

oil field, is an anticlinal trap.

Stratigraphic traps are due to depositional variation in rock type (facies changes) or truncation of the original reservoir rock. Cottonwood Creek field in the Bighorn

Basin is an excellent example of a large stratigraphic trap formed by a change from the permeable Phosphoria Formation to the impermeable Goose Egg Formation.

Unconventional Reservoirs

Conventional oil and gas resources are generally produced by vertical wells that target high porosity and permeability reservoir rocks and spatially defined hydrocarbon pools.

Unconventional oil and gas resources are typically more challenging to extract due to being distributed throughout the pore spaces of very low porosity and permeability reservoir rocks.

Because of technological advancements such as horizontal drilling and hydraulic fracturing, these previously uneconomical resources are the focus of new oil and gas exploration and development.

Unconventional resources that have contributed to Wyoming’s oil and gas industry include shale gas, tight gas and oil sands, shale oil, and coalbed natural gas. The 2011 through 2019 increase

in Wyoming’s oil production can largely be attributed to the exploration and development of stacked unconventional reservoirs in the Powder River and Denver basins, such as the Teapot, Parkman,

Sussex, Shannon, Turner, Wall Creek, Niobrara, and Codell.

![Schematic diagram showing different types of conventional and unconventional reservoirs. [Credit: WSGS] types of reservoirs](../images/energy/reservoir-types.png) Shale gas is natural gas locked in shale formations. In these reservoirs, the shale is both the source and the reservoir rock. An example of shale gas in Wyoming is

the Hillard-Baxter system in the Greater Green River Basin.

Shale gas is natural gas locked in shale formations. In these reservoirs, the shale is both the source and the reservoir rock. An example of shale gas in Wyoming is

the Hillard-Baxter system in the Greater Green River Basin.

Tight gas and oil reservoirs contain natural gas and oil trapped in the pores of siltstones and sandstones with very low permeability (<0.1 millidarcy) and very low

porosity (<10%). The prolific Jonah, Pinedale, and Wamsutter fields are Wyoming’s largest tight gas reservoirs.

Shale oil is oil locked in shales and associated tight siltstones or carbonates, all of which have low permeability and porosity. Examples from Wyoming include the

Niobrara Shale and Green River Formation. Note: shale oil should not be confused with oil shale. Oil shales are shales that contain kerogen. Generally,

hydrocarbons cannot be produced from oil shale using wells. Mining or in-situ heating processes are necessary to extract and convert the kerogen.

Coalbed natural gas (CBNG), commonly called coalbed methane, is natural gas stored in coal beds. For more information, see the Coalbed Natural Gas tab on this page.

![Wyoming coalbed methane map. [Credit: WSGS] Wyoming coalbed methane map](../images/energy/cbm-map-thumb22.jpg) Coalbed Natural Gas

Coalbed Natural Gas

Development of coalbed natural gas (CBNG), also called coalbed methane, began in Wyoming in the late 1970s, but did not boom until the 1990s, primarily in the Powder River Basin.

Because of competition from unconventional gas reservoirs and lower natural gas prices, Wyoming CBNG production has steadily declined since 2010.

![Schematic coalbed methane well diagram. [Credit: WSGS] CBM well diagram](../images/energy/cbm-well-diagram22.jpg)

How is Coalbed Natural Gas Formed?

Environments rich in plant material such as swamps, estuaries, and marshes, were prolific in Wyoming during the Eocene Epoch (56–34 million years ago)

and the Paleocene Epoch (66–56 million years ago). Time, heat, and pressure converted this organic material to coal. Coalbed natural gas formed in these coal seams by either

biogenic or thermogenic processes.

Biogenic: During the earliest stage of coalification (the process that turns plant

detritus into coal), biogenic methane is generated as a byproduct of bacterial respiration.

Aerobic bacteria (those that use oxygen in respiration) metabolize any free oxygen left in

the plant detritus and the surrounding sediments. In fresh water environments, methane production

begins immediately after the oxygen is depleted. Species of anaerobic bacteria (those that do not

use oxygen) then reduce carbon dioxide and produce methane through anaerobic respiration. When

the temperature of underground coal reaches and is maintained at approximately 122°F (50°C), biogenic

methane is generated. By this point, two-thirds of the moisture has also been expelled, and the coal reaches a rank of subbituminous.

Thermogenic: After the temperature of a coal exceeds 122°F (50°C) due to the geothermal gradient and deep burial, thermogenic

processes begin to generate additional carbon dioxide,

nitrogen, methane, and water. At this point, the amount of hydrocarbons or volatile matter has

increased and the coal reaches a rank of bituminous. When the temperature of the coal reaches

302°F (150°C), thermogenic production of methane is maximized.

Coalbed Natural Gas Extraction

In the Powder River Basin, most coalbed natural gas wells are completed open-hole. This method involves setting casing to the top of the target coalbed, under-reaming the

underlying target zone, and cleaning the coal with a fresh-water flush. A down-hole submersible pump removes water from the coal and depressurizes the aquifer. The methane

gas desorbs from the coal, flows up the annulus, and is piped to a metering facility where the gas and water production from each well is recorded. The methane then flows

to a compressor station where the gas is compressed and shipped via pipeline. The produced water is either diverted to a central discharge point (called an outfall) and

then into a drainage or impoundment, or is re-injected into nearby aquifers.

Enhanced Oil Recovery

![Schematic diagram of enhanced oil recovery with CO2 and water. [Credit: WSGS] schematic diagram of enhanced oil recovery with CO2 and water](../images/energy/ground-co2.png) Enhanced oil recovery is used to recover stranded oil that remains in reservoirs after primary depletion.

Enhanced oil recovery is used to recover stranded oil that remains in reservoirs after primary depletion.

Oil is first produced from reservoirs under primary recovery due to in-situ reservoir pressure aided by pumps. Secondary recovery generally occurs by a waterflood.

Water is injected into the reservoir to physically displace the residual oil, which is subsequently recovered by adjacent production wells. The success of waterfloods

depends on the permeability of the reservoir and the properties of the oil.

Tertiary recovery techniques are also referred to as enhanced oil recovery, or EOR. The three most common EOR techniques are heat injection, chemical injection, and gas injection.

Heat injection enhances reservoir productivity by reducing crude oil's viscosity. Chemical injection, through the interaction of various chemicals with oil, decreases surface

tension and capillary pressure within the reservoir. Gas injection is currently the most common EOR technique. The gas, usually carbon dioxide (CO2), displaces and mixes with

oil to enhance productivity. CO2 injection is commonly referred to as CO2-EOR, and the term is often used interchangeably with EOR.

CO2-EOR has been successful in several fields around Wyoming, including Lost Soldier and

Wertz fields and the Monell unit in the Patrick Draw field of the Greater Green River Basin, Salt

Creek field in the Powder River Basin, and Beaver Creek field in the Wind River Basin. Grieve

field, in the Wind River Basin, began CO2-EOR operations in early 2013. Most of these fields

underwent secondary waterflooding prior to CO2-EOR.

For more information on enhanced oil recovery in Wyoming, see the University of Wyoming’s

Enhanced Oil Recovery Institute website.

Crude Oil Classifications

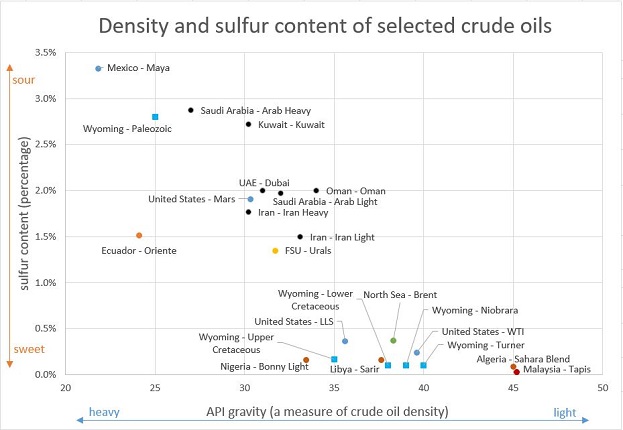

Crude oil is classified by its non-hydrocarbon content (especially sulfur), its American Petroleum Institute (API) gravity, and pricing benchmarks.

Crude oil containing low amounts of sulfur (<0.42 percent) and trace amounts of hydrogen sulfide and carbon dioxide is called sweet crude. Sweet crude oil is typically processed into gasoline. Sour

crude oil has total sulfur amounts greater than 0.5 percent and higher hydrogen sulfide (>1 percent) and carbon dioxide concentrations. Because of the impurities in sour crude, it is often converted to heavy

crude oil products, such as diesel and fuel oil.

API gravity is an indicator of how heavy crude oil is compared to water. Oil with an API > 10° is lighter than water,

while an API < 10° is heavier than water and will sink. In general, light crude oils have low viscosity, low wax content, and low density/high API gravity (>30° API).

Medium crude oil has API gravity between approximately 20° API and 30° API. Heavy crude oil is more viscous, and has a higher density/lower API gravity (10–20° API).

Extra heavy crude oil (also called bitumen) has an API gravity less than 10° API.

Because a large proportion of light sweet crude oil can be directly processed into gasoline and other petroleum products, it typically commands the highest prices on

commodity

markets. An example of light sweet crude is West Texas Intermediate (WTI) Crude from the Texas Permian Basin. It has an API gravity of ~39.6° and sulfur

content of ~0.24 percent.

WTI crude is used as a benchmark for crude oil prices, along with other common benchmarks such as North Sea Brent, the Organization of the Petroleum Exporting Countries

(OPEC) Reference Basket, and United Arab Emirates (UAE) - Dubai.

Natural Gas Categories

Natural gas is often categorized based on its liquid content. Dry natural gas is almost entirely methane and can be extracted from traditional reservoir rocks or from coal

seams. It contains less than 0.1 gallon of liquid fractions per 1,000 cubic feet of produced gas.

Wet natural gas contains a larger proportion of natural gas liquids than dry gas. Natural gas liquids (NGLs) are fractions of natural gas that are liquid at surface conditions

and are often separated from dry natural gas in processing facilities. NGLs with a low vapor pressure are called condensates, while NGLs with medium and high vapor pressures

are called natural gasoline and liquefied petroleum gas, respectively. Examples of NGLs include propane, butane, isobutene, hexane, heptane, and pentane. Ethane is not typically

considered an NGL because it needs to be refrigerated in order to maintain a liquid state. Wet gas typically sells at higher prices than dry gas.

Modified from U.S. Energy Information Administration to include select Wyoming crude oils.

Modified from U.S. Energy Information Administration to include select Wyoming crude oils.

WTI = West Texas Intermediate; LLS = Louisiana Light Sweet; FSU = Former Soviet Union; UAE = United Arab Emirates.