Wyoming Bentonite

![American Colloid Company, Colony, Wyoming plant. [Credit: Wayne Sutherland, WSGS] Bentonite-plant](../images/minerals/bentmill-colony.jpg) Bentonite includes any natural material dominantly composed of clay minerals in the smectite group.

Wyoming bentonite consists of hydrous silicate of alumina, commonly referred to as montmorillonite

clay. Also known as sodium bentonite, Wyoming bentonite is high-swelling sodium montmorillonite

clay, of which its end market percent uses are: kitty litter (25 percent), drilling mud

(20 percent), binder in foundry molds (19 percent), iron ore pelletizing (13 percent), and other

applications (23 percent). Wyoming bentonite can swell up to 16 times its original size and absorb

up to 10 times its own weight in water. Calcium bentonite, a low or non-swelling variety, is

relatively unimportant in Wyoming production.

Bentonite includes any natural material dominantly composed of clay minerals in the smectite group.

Wyoming bentonite consists of hydrous silicate of alumina, commonly referred to as montmorillonite

clay. Also known as sodium bentonite, Wyoming bentonite is high-swelling sodium montmorillonite

clay, of which its end market percent uses are: kitty litter (25 percent), drilling mud

(20 percent), binder in foundry molds (19 percent), iron ore pelletizing (13 percent), and other

applications (23 percent). Wyoming bentonite can swell up to 16 times its original size and absorb

up to 10 times its own weight in water. Calcium bentonite, a low or non-swelling variety, is

relatively unimportant in Wyoming production.

Bentonite,

originally known as “mineral soap” or “soap clay,” was named “bentonite” in 1898 by Wilbur C. Knight for

deposits in the Benton Shale near Rock River, Wyoming. The Benton Shale included Upper and Lower Cretaceous units lying between the Niobrara and Cloverly formations and their equivalents. Currently named equivalent stratigraphic units in Wyoming include the Frontier Formation, Carlile Shale, Greenhorn Formation, Belle Fourche Shale, Mowry Shale, Aspen Shale, Muddy Sandstone, Newcastle Sandstone, Thermopolis Shale, Skull Creek Shale, and Bear River Formation. The best Wyoming bentonite is found primarily in the Upper Cretaceous Mowry Shale.

According to the Wyoming

Mining Association, bentonite deposits in Wyoming comprise as much as 70 percent of the world's known supply, making the state the nation's leader in bentonite production.

Surface mining to depths no greater than about 50 feet accounts for all bentonite

production. Bentonite is mined in Wyoming from numerous pits in various areas of the state. Major

producing districts are the Northern Black Hills (Colony) District, Southern Black Hills

(Clay Spur) District, Kaycee District west of Kaycee, and Eastern Big Horn Basin. Bentonite

from pits in these areas is blended, ground, dried, and processed into various products at 15

active mills in Wyoming.

Summary Report

Wyoming Bentonite

Download the 2014 Wyoming Bentonite Summary Report.

![Bentonite soil from the Mowry Formation. [Credit: Wayne Sutherland, WSGS] Bentonite-plant](../images/minerals/bentonite.jpg)

- ►References

-

Hosterman, J.W., and Patterson, S.H., 1992, Bentonite and fuller’s earth

resources of the United States: U.S. Geological Survey Professional Paper 1522,

1 pl., 45 p.

Virta, R.L., 2005, Clays: U.S. Geological Survey Mineral Commodity Summaries

2005, 2p.

Additional Information

Bentonite

Performance Minerals, Inc

Black Hills

Bentonite

CETCO

Wyo-Ben

Wyoming Mining

Association

Wyoming Construction Aggregate

Natural aggregate is one of our most abundant, accessible, and widely used natural resources.

Construction aggregate consists of sand, gravel, and crushed stone.

It is primarily used by highway and building construction industries.

Wyoming’s energy industry also requires large amounts of aggregate for the construction of well pads, wind generator bases, and access roads to industrial sites.

Aggregate Industry Facts

- More than 2.5 billion tons of aggregate (construction-grade crushed stone [1.5 billion tons] and sand and gravel [1 billion tons])

were produced for every person in the United States in 2017 (based on U.S. Geological Survey [USGS] Mineral Industry Surveys production and U.S. Census population estimates).

- It takes 400 tons of aggregate to build the average home in America, according to the National Stone, Sand and Gravel Association.

- Construction of one mile of interstate highway is estimated to require 38,000 tons of aggregate, according to the National Stone,

Sand and Gravel Association. The Wyoming Department of Transportation indicated a mile of Wyoming highway may contain more than double that amount,

depending on the aggregate quality, native soils, and use of the road.

Additional Information

National Stone, Sand and Gravel Association

State of Wyoming Department of Revenue

State of Wyoming Department of Workforce Services

USGS Mineral Industry Surveys

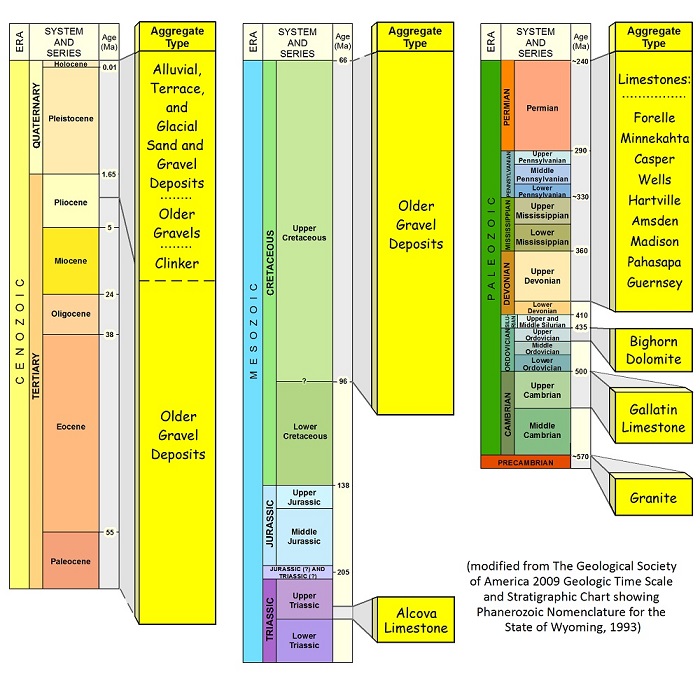

Aggregate Geology

Wyoming has a variety of geologic landscapes providing plentiful aggregate resources including the following:

Sand is acquired from alluvial floodplains along stream and river valleys as well as from extensive dune sands.

Windblown sand deposits occur between the western Green River Basin through Wyoming and into western Nebraska.

Sand and gravel deposits occur on the tops of benches and terraces along mountain flanks.

The quality of these deposits varies greatly, as terraces may contain areas of caliche.

Caliche-coated gravels do not bind well with asphalt or cement.

Glacial gravels are not widely used due to location in national parks and national forests.

However, they are occasionally used for local road construction projects.

Older gravels from poorly consolidated conglomerates are a source of “natural gravel"

that are useful if they can be extracted without blasting or cutting.

Limestone is exposed along the flanks of mountain ranges and is a significant source of crushed stone.

Limestone is the preferred rock for highway construction.

Granite is another source of crushed stone. Specifically, quartzofeldspathic gneiss is mined in the largest aggregate quarry in Wyoming,

west of Cheyenne. Railroad ballast is one of the quarry’s main product, simply because the foliation in the gneiss allows the rock to have a

2:4:6 dimensional ratio, which is a requirement of certain types of railroad ballast.

Clinker, also called scoria or baked and fused rock, is formed by the burning, baking, and melting of strata overlying burning coal beds.

Clinker is found and used extensively in the Powder River Basin (PRB), where no other aggregate sources exist.

It is used for the sub-base of roads and for well-pad construction. Although it is abundant in the PRB,

clinker is not as durable and breaks down more easily than sand and gravel.

Mine tailings are a unique source of gravel in the South Pass mining district and are used locally for road building.

Aggregate Recycling and Renewal

Recycling of aggregate, primarily re-crushing concrete and asphalt, is economically viable in many situations. The Wyoming Department of Transportation recycles and turns into new pavement nearly all

the asphalt and concrete pavement they remove from Wyoming’s roadways. There are also various processes for creating lightweight synthetic aggregate from waste products such as coal ash and sewer sludge.

Recycled aggregate sources help relieve shortages and reduce landfill waste.

Summary Report

Wyoming's Construction Aggregate Resource

Download the 2015 Wyoming's Construction Aggregate Resource Summary Report.

- ►References

-

State of Wyoming Department of Workforce Services, 2021, Annual Report of the State Inspector of Mines of Wyoming:

State Inspector of Mines of Wyoming.

State of Wyoming Department of Revenue, 2021, State of Wyoming Department of Revenue Annual Report:

State of Wyoming Department of Revenue Annual Report, 79 p.

USGS Minerals Industry Surveys, 2022, Crushed stone statistics and information:

United States Geological Survey Quarterly Reports.

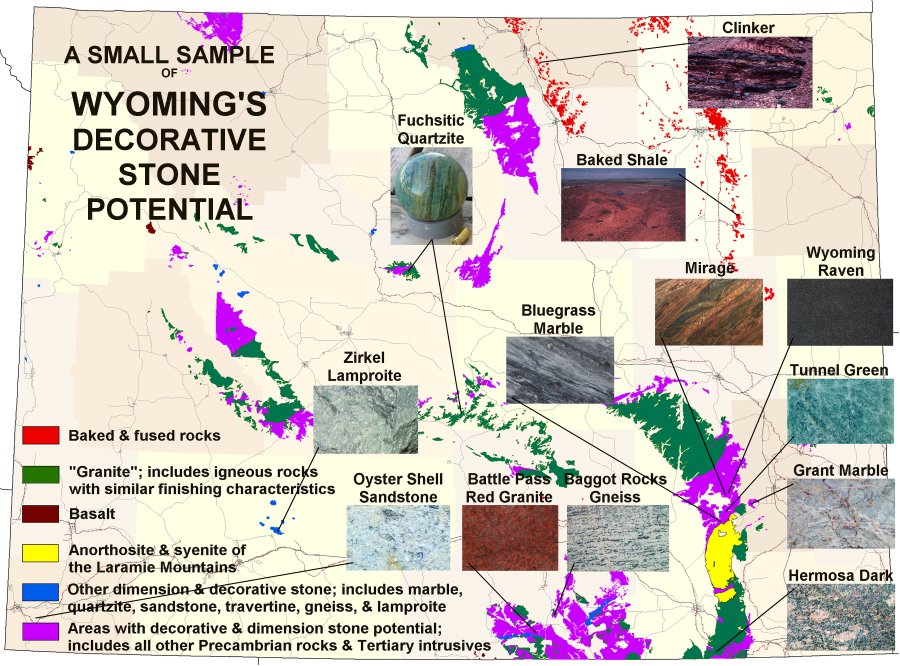

Wyoming Decorative Stone

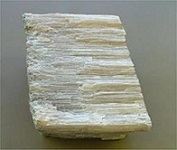

![Grant Ranch marble. [Credit: R.E. Harris] marble](../images/minerals/marble.jpg) Wyoming contains a wide variety of granite, marble, sandstone, quartzite,

gneiss, limestone, and volcanic rocks suitable for use as decorative stone.

Because the United States imports approximately 80 percent of the dimensional stone used in

interior and exterior construction, the decorative stone industry has great

potential for growth. With convenient transportation and a wide variety of rock

types and colors available, Wyoming is one of the most promising locations for

expansion of this industry. Limited exploration for stone has occurred in

southern Wyoming during the past 12 years. Requests for local stone products,

rather than imports, appear to be driving a small interest in Wyoming

stone.

Wyoming contains a wide variety of granite, marble, sandstone, quartzite,

gneiss, limestone, and volcanic rocks suitable for use as decorative stone.

Because the United States imports approximately 80 percent of the dimensional stone used in

interior and exterior construction, the decorative stone industry has great

potential for growth. With convenient transportation and a wide variety of rock

types and colors available, Wyoming is one of the most promising locations for

expansion of this industry. Limited exploration for stone has occurred in

southern Wyoming during the past 12 years. Requests for local stone products,

rather than imports, appear to be driving a small interest in Wyoming

stone.

Dimensional stone is quarried in large blocks by sawing or drilling the stone.

The material is then either processed on site or shipped by truck to a

fabricating plant.

Wyoming contains extensive outcrops of rocks of many different colors and

lithologies suitable for use as decorative and dimensional stone. Currently, the

only dimensional stone quarry is Strid Marble & Granite’s Rawlins sandstone

quarry in the Cretaceous Mesa Verde Formation, located southeast of Rawlins, Wyoming.

Strid operates a stone fabrication plant near Cheyenne.

In the past, stone quarried in Wyoming was mostly used locally. Quarries near

developing towns provided stone blocks for public and private buildings, curbs,

walkways, and other purposes. During the late 1800s, three quarries in Wyoming

shipped stone to out-of-state markets. The Waterfall Quarry near Kemmerer in

western Wyoming was the source of the stone used to construct and face the city

hall in Portland, Oregon. A gray sandstone quarry near Rawlins supplied dimensional

blocks for construction of the Wyoming State Capitol in Cheyenne, the Union Pacific Railroad

depot in Ogden, Utah, and several buildings in northern Colorado. The University Quarry in the Casper Formation near

Laramie furnished stone for about half of the buildings on the University of

Wyoming campus. Some stone from this quarry was also used on private buildings

in Laramie and Cheyenne, and Fort Collins, Colorado.

![Raven Quarries’ Mirage Granite. [Credit: R.E. Harris] Raven granite](../images/minerals/raven-granite.jpg) From the early 1900s through the 1950s, the Jay Em Stone Company in Jay Em

quarried granite, marble, onyx, quartzite, and other rock types in

eastern Wyoming and in the Black Hills of South Dakota for use as monuments and

other products. In the 1950s and 1960s, Basins, Inc. of Wheatland

quarried and sold several types of decorative aggregate including green

serpentine and various colors of marble. In the late 1970s, Georgia Marble

acquired Basins and continued quarrying white marble west of Wheatland and

processing it into decorative aggregate. Georgia Marble was purchased by Imerys

Marble in March 2000, and the pit operation closed in March 2004.

From the early 1900s through the 1950s, the Jay Em Stone Company in Jay Em

quarried granite, marble, onyx, quartzite, and other rock types in

eastern Wyoming and in the Black Hills of South Dakota for use as monuments and

other products. In the 1950s and 1960s, Basins, Inc. of Wheatland

quarried and sold several types of decorative aggregate including green

serpentine and various colors of marble. In the late 1970s, Georgia Marble

acquired Basins and continued quarrying white marble west of Wheatland and

processing it into decorative aggregate. Georgia Marble was purchased by Imerys

Marble in March 2000, and the pit operation closed in March 2004.

Raven Quarries operated a site in northern Albany County where it produced two

types of granitic rocks until 2003. A black amphibolite, Wyoming Raven, quarried

here was used to construct Bill Gates' house in Seattle, Washington.

Strid Marble & Granite Company currently quarries Wyoming granite and red sandstone in

Carbon and Converse counties, respectively. Large blocks of quarried stone are removed from the

outcrop, and finishing work is completed by the Dakota Granite Company where the stone is

prepared for final applications. Some of this stone was used in the remodeling work on the

Herschler Building in Cheyenne.

Other contracts include decorative accents in federal buildings, church

cornerstones, and monuments. The variegated pink granite, first called

Fantastico, then Mirage, was quarried until February 2003.

Wyoming continues to produce decorative aggregate and fieldstone, most of which

is sold to the Colorado Front Range and Utah Wasatch Front markets. However,

distributors in California, Illinois, and elsewhere have expressed interest in

some of these products and have purchased small amounts of material for market

testing. Wyoming hosts nearly as many different colors and varieties of stone as

the rest of the world combined.

However, no dimension stone quarries are currently active in Wyoming.

Recommended Decorative Stone References

Further information on Wyoming’s decorative stone resources can be found in the

following WSGS publications, both of which present colorful summaries of the

wide variety of decorative stones found in Wyoming.

Harris, R.E., 1991, Decorative stones of Wyoming: Geological Survey of Wyoming [Wyoming State Geological Survey] Public Information Circular 31, 27 p.

Harris, R.E., 2003, Decorative stones of southern Wyoming: Wyoming State Geological Survey Public Information Circular 42, 55 p.

Wyoming Gypsum

![British Paper Board (BPB) gypsum plant in Cody, Wyoming. [Credit: R.E. Harris] marble](../images/minerals/gypsum-plant.jpg) Gypsum is mined at three locations in Wyoming. Mountain Cement mines small

amounts of gypsum near Laramie for use as a retardant in cement. Two plants in

the Bighorn Basin of northwest Wyoming mine gypsum and process it into wallboard

at nearby plants. The gypsum wallboard plants in Wyoming, the Georgia-Pacific

Himes gypsum mill, and the Certain Teed Gypsum & Ceiling Manufacturing, Inc. gypsum mill in Cody

have operated at capacity since

1995. Construction booms in the Wyoming market areas of the Colorado Front

Range, Utah Wasatch Front, and Pacific Northwest have increased the demand for

construction materials, including wallboard. Wyoming has large gypsum resources capable of supporting additional production.

Gypsum is mined at three locations in Wyoming. Mountain Cement mines small

amounts of gypsum near Laramie for use as a retardant in cement. Two plants in

the Bighorn Basin of northwest Wyoming mine gypsum and process it into wallboard

at nearby plants. The gypsum wallboard plants in Wyoming, the Georgia-Pacific

Himes gypsum mill, and the Certain Teed Gypsum & Ceiling Manufacturing, Inc. gypsum mill in Cody

have operated at capacity since

1995. Construction booms in the Wyoming market areas of the Colorado Front

Range, Utah Wasatch Front, and Pacific Northwest have increased the demand for

construction materials, including wallboard. Wyoming has large gypsum resources capable of supporting additional production.

Recommended Gypsum References

Bullock, J.M., and Wilson, W.H., 1969, Gypsum deposits in the Cody area, Park County, Wyoming:

Geological Survey of Wyoming [Wyoming State Geological Survey] Preliminary Report 9, 12 p., 1 pl.

Wyoming Trona

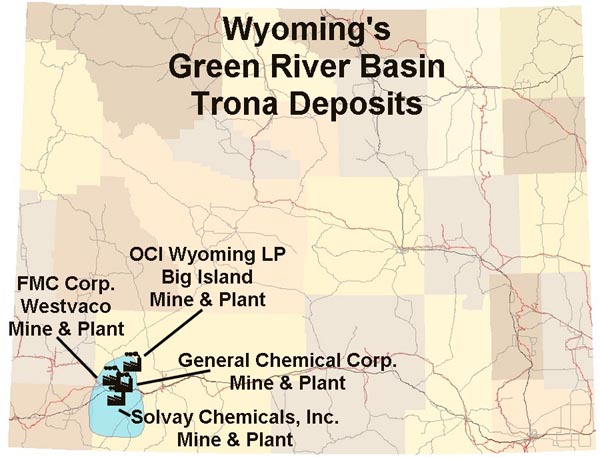

Wyoming hosts the world's largest trona deposits, an estimated resource of 127 billion tons. Of this, 40 billion tons

are mineable using conventional “hard rock” methods.

![Aerial view of the OCI trona mine and plant. [Credit: R.E. Harris] marble](../images/minerals/trona-plant.jpg) Trona, or natural soda ash, is a sodium sesquicarbonate compound that occurs as an evaporite mineral in the Wilkins Peak

Member of the Eocene Green River Formation in southwest Wyoming. Trona, which is

70 percent sodium carbonate, is refined to produce sodium compounds, particularly soda

ash. Baking soda is pure soda ash. Soda ash is the second ingredient by

weight in glass after silica, where it lowers the melting temperature of silica

sand. It is also used in soaps, detergents, inorganic chemicals, water

purification, flue gas desulfurization, and a number of other products and

processes. The manufacture of compounds such as sodium phosphate, caustic soda, and sodium cyanide (used in gold refining), also depends on trona.

Trona, or natural soda ash, is a sodium sesquicarbonate compound that occurs as an evaporite mineral in the Wilkins Peak

Member of the Eocene Green River Formation in southwest Wyoming. Trona, which is

70 percent sodium carbonate, is refined to produce sodium compounds, particularly soda

ash. Baking soda is pure soda ash. Soda ash is the second ingredient by

weight in glass after silica, where it lowers the melting temperature of silica

sand. It is also used in soaps, detergents, inorganic chemicals, water

purification, flue gas desulfurization, and a number of other products and

processes. The manufacture of compounds such as sodium phosphate, caustic soda, and sodium cyanide (used in gold refining), also depends on trona.

Trona is white, gray, amber, or yellow with vitreous, or glass-like, luster.

Trona is soluble in a dilute (10 percent) hydrochloric acid and water solution. It has

a monoclinic crystal structure and is soft, about 2.5 to 3 on the 10-point Mohs

hardness scale. For a better understanding of crystal structure, hardness, and

other characteristics of trona and other minerals, WSGS Bulletin No.72, Minerals

and Rocks of Wyoming, or a mineralogy text is recommended.

Trona deposits were first discovered in Wyoming during October 1937 when Mountain Fuel Supply

Company took core samples from the John Hay #1 well while drilling for oil and gas. Core from this well

contained thick zones of trona and other evaporite minerals, some of which (such as shortite) were identified for the first time.

In 1939, the U.S. Geological Survey began a strategic minerals study and in 1940, published a reference to the minerals

found in this core. Westvaco Chemical Corporation produced the first trona from trona Bed 17 at a depth of 1,500 feet in

1947.

Trona currently forms as an evaporite mineral in places such as Africa and

California. Wyoming’s trona is believed to have formed in the same manner.

During the Eocene (48 million to 53 million years ago), an immense lake known as Lake

Gosiute occupied the Green River Basin. Over millions of years, Lake Gosiute

expanded and contracted due to regional climatic cycles. During intervals of

dryness and evaporation, Wyoming’s rich trona deposits were deposited in parts

of the Wilkins Peak Member of the Green River Formation. The Wilkins Peak mMmber

consists of trona beds up to 40 feet thick separated by lake-bottom shaly

sediments, sandstone, and carbonate rocks. Trona beds in the Wilkins Peak member

lie at depths of 600 to 2,000 feet beneath the Green River Basin. Other members

of the Green River Formation are sediments deposited in a freshwater lake

environment. For detailed geologic information on the various theories of trona

formation, see

WSGS Public Information Circular No. 40.

Trona currently forms as an evaporite mineral in places such as Africa and

California. Wyoming’s trona is believed to have formed in the same manner.

During the Eocene (48 million to 53 million years ago), an immense lake known as Lake

Gosiute occupied the Green River Basin. Over millions of years, Lake Gosiute

expanded and contracted due to regional climatic cycles. During intervals of

dryness and evaporation, Wyoming’s rich trona deposits were deposited in parts

of the Wilkins Peak Member of the Green River Formation. The Wilkins Peak mMmber

consists of trona beds up to 40 feet thick separated by lake-bottom shaly

sediments, sandstone, and carbonate rocks. Trona beds in the Wilkins Peak member

lie at depths of 600 to 2,000 feet beneath the Green River Basin. Other members

of the Green River Formation are sediments deposited in a freshwater lake

environment. For detailed geologic information on the various theories of trona

formation, see

WSGS Public Information Circular No. 40.

Summary Report

Wyoming Trona

Download the 2014 Wyoming Trona Summary Report.

- ►References

-

Dyni, J.R., 1997, Sodium carbonate resources of the Green River Formation,

in Jones, R.W., and Harris, R.E., eds., Proceedings of the 32nd

Annual Forum of Industrial Minerals—Laramie, Wyoming, May 19–21, 1996: Wyoming State Geological Survey Public Information Circular 38, p.123–143.

Garrett, D.E., 1998, Origin of the Green River trona deposit (from a chemical

and other saline mineral perspective, in Dyni, J.R., and Jones,

R.W., eds.,

Proceedings of the first international soda ash

conference volume II Wyoming State Geological Survey Public Information

Circular 40, p. 15–20.:

Hausel, W.D., 2005, Minerals and rocks of

Wyoming: Wyoming State Geological Survey

Bulletin 72, 159 p.

Kostick, D.S., 1994, Soda ash in Carr, D.D., ed.,

Industrial minerals and rocks, 6th edition: Society for Mining, Metallurgy

and Exploration, Inc., p.929–958.

Kostick, D.S., 1998,

The origin of the U.S. natural and synthetic soda ash

industries, in Dyni, J.R., and Jones, R.W., eds.,Proceedings

of the first international soda ash conference volume I: Wyoming State

Geological Survey Public Information Circular 39, p.11–33.

Kostick, D.S., 2007, Soda ash, in U.S. Geological Survey Mineral Commodity

Summaries, 2006, p.150–151, accessed March 2007, at

http://minerals.usgs.gov/minerals/pubs/commodity/soda_ash/sodaamcs07.pdf.

Leigh, R.T., 1997, Wyoming Trona–An overview of the geology, in

Jones, R.W., and Harris, R.E., eds., Proceedings of the 32nd

Annual Forum of Industrial Minerals–Laramie, Wyoming, May 19–21, 1996: Wyoming

State Geological Survey Public Information Circular 38, p. 319.

Leigh, R.T., 1998, Wyoming trona: An overview of the geology, in Dyni,

J.R., and Jones, R.W., eds., Proceedings of the first international soda ash

conference volume II: Wyoming State Geological Survey

Public Information Circular 40, p. 1–14.

Mendenhall, W.C., 1940, Occurrence of a deposit of trona: Science, v.91,

no. 239, p.11–12.

Additional Information

FMC Corporation

General

Chemical

OCI Chemical Corporation

Solvay

Chemicals

Introduction

Phosphate rock is the primary source of phosphorus for industrial applications. Phosphorus in phosphate rock most commonly occurs within apatite

(Ca5(PO4)3(F,Cl,OH). Apatite is found in sedimentary, igneous, and metamorphic rocks. There are six economic deposit

types for phosphate rock: 1) marine phosphorites, 2) igneous apatite, 3) residual phosphorites,

4) river pebble phosphate deposits, 5) phosphatized rock, and 6) guano.

Phosphate Rock in Wyoming

Download the Phosphate Rock in Wyoming report.

Applications

The primary industrial application of phosphate rock is the production of fertilizer used to add

phosphorus to soil. Phosphorus (P) is a nutrient vital for all life as a component in DNA and RNA,

and also adenosine triphosphate, which facilitates energy transfer within cells. Terrestrial plants

incorporate phosphorus from soil, while animals receive phosphorus through their diet. In nature,

phosphorus is often a limiting factor with respect to the quantity of life an ecosystem can

support. In soil, natural soluble phosphorus that can be taken up by plants typically makes up less

than 10 percent of total phosphorus in the soil. In agricultural settings, natural availability of

soluble phosphorus is prohibitively low, thus phosphorus must be added to the soil by means of a

topical fertilizer. Similarly, phosphorus feed-additives may be required for ruminant livestock.

Production

The United States is the third largest producer of phosphate rock globally. Currently, the bulk of

domestic production occurs in Florida and North Carolina, with remaining production in Idaho and

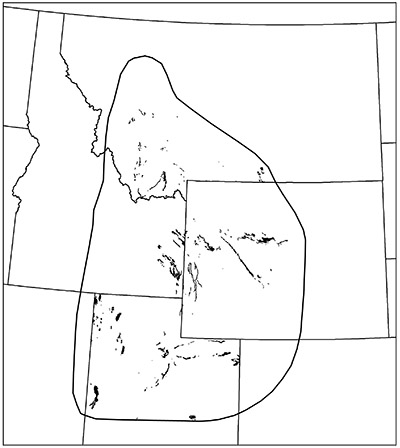

Utah. Phosphate production in Idaho and Utah is from the so-called Western Phosphate Field, an area

covered by the Permian-aged Phosphoria Formation. The eastern portion of the Western Phosphate

Field covers the western half of Wyoming. Though the Phosphoria Formation thins eastward from Idaho

into Wyoming, notable phosphate rock deposits within the Phosphoria Formation are present in Wyoming.

At present, there are no active phosphate rock mines in Wyoming, though mining did occur

intermittently through the 20th century. Phosphate rock in Wyoming was first mined in 1907, and

production in the western portion of the state continued sporadically until the opening of the

Leefe mine in 1947. Production of phosphate rock in Wyoming last occurred in 1977. The Leefe Mine,

located approximately 30 miles west of Kemmerer, produced phosphate rock from 1947 to 1977 from the

Phosphoria Formation. Although production in Wyoming has been dormant for more than 35 years, the phosphate mining industry has a robust presence in southeastern Idaho and northeastern

Utah, and a phosphate processing facility is located near Rock Springs, Wyoming. Thus, phosphate

rock deposits in western Wyoming are relatively close to existing phosphate processing

infrastructure.

Wyoming Occurrences

![Close-up photograph showing typical texture of phosphate rock from the Phosphoria Formation. [Credit: Jacob Carnes, WSGS]](../images/minerals/phosphate-micropictograph.jpg)

Of the six deposit types listed above, only marine phosphorites and igneous apatite are known to

occur in Wyoming. Marine phosphorites are well documented within the Permian Phosphoria Formation

of western to central Wyoming; these are the only phosphate rock occurrences in Wyoming likely to

be of a grade and extent to attract economic interest. No extensive high-grade igneous phosphate

deposits are known in Wyoming, but the typical host rock-types are not uncommon to the state, and

anomalously high concentrations of igneous apatite have been recognized in the state. In the central Laramie Range, apatite is associated with

magnetite-ilmenite deposits within the Laramie Anorthosite Complex. Magnetite-ilmenite bodies at

the Taylor Deposit host up to 60 percent apatite. Apatite also was identified at two other

magnetite-ilmenite deposits, which were labeled deposits #1 and #6. At deposit #1, varying amounts

of apatite occur within iron-rich lenses. At deposit #6, apatite is abundant within an irregular

dike, though a sample of this dike yielded only slightly greater than 2 percent P2O5.

have been recognized in the state. In the central Laramie Range, apatite is associated with

magnetite-ilmenite deposits within the Laramie Anorthosite Complex. Magnetite-ilmenite bodies at

the Taylor Deposit host up to 60 percent apatite. Apatite also was identified at two other

magnetite-ilmenite deposits, which were labeled deposits #1 and #6. At deposit #1, varying amounts

of apatite occur within iron-rich lenses. At deposit #6, apatite is abundant within an irregular

dike, though a sample of this dike yielded only slightly greater than 2 percent P2O5.

Thick, medium- to high-grade occurrences of phosphate rock of the Phosphoria Formation are most

common in western Wyoming, but may extend into central Wyoming. The Meade Peak Member of the

Phosphoria Formation in the Overthrust Belt exhibits the highest potential for economically viable

phosphate rock deposits with respect to grade and thickness; however, the steep inclination and

discontinuity of beds may preclude mineability at many locations. All historic phosphate mining

in Wyoming targeted the Meade Peak Member in the Overthrust Belt. Southeast of Lander, the Meade

Peak Member and, to a lesser degree, the Retort Member of the Phosphoria Formation host important

phosphate deposits along the northeastern flank of the Wind River Range. The Lander deposits

are low- to medium-grade, but the structural geology of the area is relatively simple compared to

the Overthrust Belt.

Wyoming Phosphate Occurrences

Wyoming Phosphate Occurrences

- ►References

-

Allaway, W.H., 1962, Relation of soil to plant and animal nutrition, in Proceedings, Cornell Nutrition Conference: Cornell University, Ithaca, New York, p. 13–23.

Diemer, R.A., 1941,

Titaniferous magnetite deposits of the Laramie Range, Wyoming: Geological Survey of Wyoming [Wyoming State Geological Survey], Bulletin 31, 23 p.

Environmental Literacy Council, 2013, Phosphorus cycle, accessed April 2015, at http://www.enviroliteracy.org/article.php/480.html.

Jasinski, S.M., 2015, Phosphate rock, in

Mineral commodity summaries 2015: U.S. Geological Survey, p. 118–119.

Jasinski, S.M., Lee, W.H., and Causey, J.D., 2004, The history of the Western Phosphate Field, in Hein, J.R., ed.,

Life cycle of the Phosphoria Formation: Handbook of Exploration and Environmental Geochemistry, v. 8: Amsterdam, Elsevier, p. 45–61.

McKelvey, V.E., Cathcart, J.B., Altschuler, Z.S., Swanson, R.W., and Lutz, Katherine, 1953,

Domestic phosphate deposits: U.S. Geological Survey Open-File Report 53-165, 49 p.

Osterwald, F.W., Osterwald, D.B., Long, J.S., Jr., and Wilson, W.H., 1966, Mineral resources of Wyoming: Geological Survey of Wyoming

[Wyoming State Geological Survey] Bulletin 50, 287 p.

Ozanne, P.G., 1980, Phosphate nutrition of plants – a general treatise, in Khasawneh, F.E., Sample, E.C., and Kamprath, E. J. eds.,

The role of phosphorus in agriculture: Madison, Wis., American Society of Agronomy, Crop Science Society of America, Soil Science Society of America, p. 559–590.

Reid, R.L., 1980, Relationship between phosphorus nutrition of plants and the phosphorus nutrition of animals and man,

in Khasawneh, F.E., Sample, E.C., and Kamprath, E.J. eds., The role of phosphorus in agriculture: Madison, Wis., American Society of Agronomy, Crop Science Society of America, Soil Science Society of America, p. 847–886.

Underwood, E.J., and Suttle, E.J., 1999, The mineral nutrition of livestock, 3d edition: Wallingford, UK, CAB International, 614 p.

Wyoming Department of Revenue, 1973–1978 Annual report: Cheyenne, Wyoming.

Wyoming State Board of Equalization, 1926–1972 Biennial report: Cheyenne, Wyoming.

Introduction

Lithium is the earth’s 25th most abundant element. It is present in many geologic materials but almost always in low concentrations. Metallic lithium is so reactive with water

and air that it does not occur naturally in its pure state, but only in the form of various salts. Lithium is required for a wide range of industrial and manufacturing uses,

but is perhaps better known for its role in batteries, especially for electric vehicles.

Production

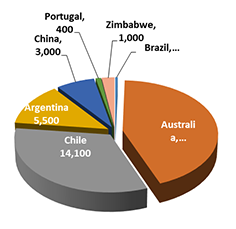

Currently, most of the world’s lithium is produced from shallow brine deposits that underlie saline lakes in the Atacama Desert of South America and from a spodumene mine in Australia.

Australia, Chile, China, Argentina, and Brazil produce most of the world’s lithium compounds, while minor amounts are produced by Portugal, Zimbabwe, and Canada. Production in the United

States is limited to a single brine operation in Silver Peak, Nevada, and commercial production from brine-sourced magnesium waste tailings. Lithium concentrations in producing brine

deposits typically exceed 200 parts per million (ppm); concentrations in lithium mineral ores are higher than 5,000 ppm. Furthermore, the facilities that produce lithium at these minimal

concentrations operate under financially advantageous conditions such as low production costs or reduced capital expenditures.

Mineral companies are looking for other sources of lithium throughout the world and in North America as industrial demands grow. Recycling, too, will provide additional sources, although the

technology is in the early stage of development. In the United States, exploration is primarily targeting Cenozoic-aged intracaldera sediments and lacustrine clays in playas across the Basin

and Range Province. Li concentrations in these sediments can exceed 3,000 ppm (Lithium Americas Corp., 2022). Hard-rock sources of lithium are typically derived from lithium-cesium-tantalum

pegmatites, which can host the minerals spodumene, lepidolite, and petalite.

Wyoming Occurrences

The WSGS reviewed geochemical data for nearly 68,000 Wyoming sediment, soil, rock, and water samples obtained from seven state and federal databases.

Additionally, WSGS geologists collected nearly 100 rock and soil samples for this study, which were evaluated along with more than 600 other WSGS samples collected in

conjunction with other projects. Together, the database records and WSGS collected samples produced lithium concentration data for 26,386 samples of Wyoming geo-materials.

The results of this study show lithium occurs in low levels in soils, groundwater, and rocks across Wyoming. With the exception a small deposit of spodumene, a lithium-enriched

mineral, in the Rattlesnake Hills of southwestern Natrona County, lithium concentrations in Wyoming deposits are substantially lower than those found at the world’s currently

producing sites. Small amounts of spodumene were mined at the Natrona County site during World War II, and spodumene is documented in isolated, small, pegmatitic occurrences

near the Owl Creek Mountains. More information can be found in the 2015 report on lithium resources.

Additional Information

For more information, see the U.S. Geological Survey’s publication on lithium and annual

Mineral Commodity Summaries for lithium and other commerical minerals.

- ►References

-

USGS Mineral Commodity Summaries

USGS periodical on lithium

LithiumAmericas Feasibility Study